A word from Hervé Lefébure, CEO from Avertim:

“ We are proud to support leading pharmaceutical and medtech companies in the battle against COVID-19. It shows that we are well placed and experienced to help them perform quick turns of focus to implement technical and organization changes in highly regulated environments. We are looking forwarding to discussing with you how Avertim can support your teams."

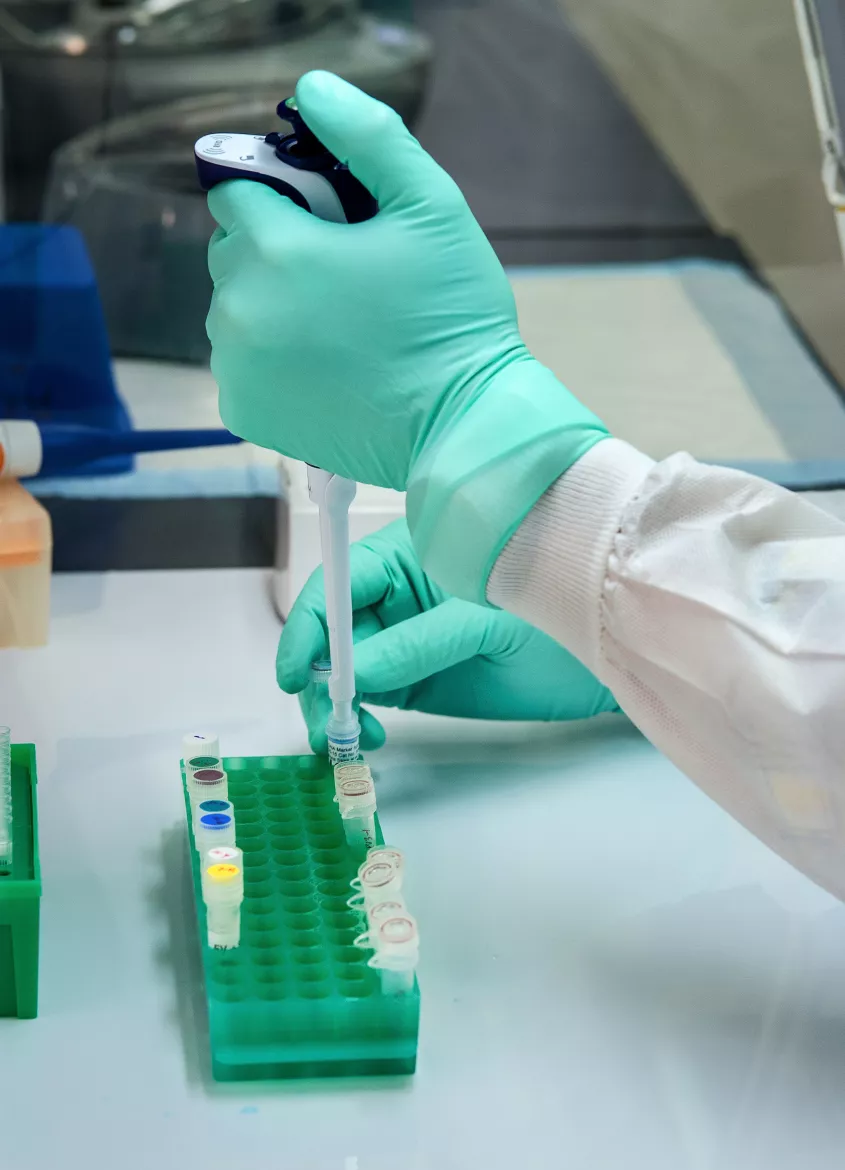

Together with a Belgian In-Vitro-Diagnostics manufacturer for the design of SARS-CoV-2 PCR test kits

Avertim has been working together with an innovative molecular diagnostics company committed to revolutionize molecular testing with its unique proprietary platform. In 2020 we have been supporting the Quality Assurance department of this client to develop new PCR test kits. We have worked on:

- QA oversight to design and develop PCR based SARS-CoV-2 test,

- Support in design control (FDA, ISO 13485) and risk management,

- Define and document design output to allow an adequate evaluation of conformance to design input,

- Design verification (analytical performance and software verification) and validation,

- Design Review Risk analysis,

- Follow-up and change control.

Our team is proud to be part of bringing efficient testing technologies to the market!

One of our Life Sciences consultant working in the team shared

“When the pandemic hit, the client specialized in oncology assays saw it as an opportunity to develop a Covid-19 test on their innovative diagnostics platform that gives a result within 90 minutes and requires minimal effort from the user. Ambitious plans were made to launch a Covid-19 test in the US under an Emergency Use Authorization (EUA). Within 4 months, we were able to design and launch a performant Covid-19 test as the company’s first IVD on the US market. Our main challenge was to make sure all design controls were in place and device quality was guaranteed regardless of the ultra-high pace of the development trajectory. A high-quality medical device is even more crucial in a pandemic setting where doctors in strained Intensive Care Unite settings must rely on the results of the IVD tests to make patient decisions. An in-depth risk analysis of the design was performed considering the use case of an infectious disease test ensuring patient and user safety”.

Together with a German In-Vitro-Diagnostics manufacturer for the production of SARS-CoV-2 PCR test kits

Avertim has been supporting since the beginning of 2020 a diagnostic manufacturer based in Germany. The company was looking for expertise to run important quality and compliance changes among which:

- Optimizing CAPA processes

- Implementing electronic Quality Systems and Training modules

- Improving tools and processes for the release and tracking of products along the logistic chain

Later in the year, the company initiated a new strategic alliance in order to produce a new innovative PCR test kits on behalf of a German healthcare. The challenge here was to prepare and ramp-up the site for production with high quality requirements. We are supporting them to optimize efficiency and the production outputs (+50% after our first month of work) by:

- Analyzing processes by collecting site data, observing ways of working, interviewing technical and management stakeholders,

- Implementing new control systems, optimizing the steering and governance processes,

- Implementing a new process for fast reaction to customer complaints,

- Identifying measures to reduce lead time of different process steps.

Together with a global pharmaceutical company for its COVID-19 vaccines clinical trials

Avertim has been supporting a global pharmaceutical company in its clinical development for a COVID-19 vaccine. Our consultants are part of a project team responsible for planning clinical trials (phase I to III). They have provided operational support in the planning and coordination of the trials, focusing especially on:

- Clinical forecasting

- Budgeting

- Data integrity

Our consultants shared

" Working on this project is very interesting as the fast timelines allow you to get immersed in the entire process, but it can be challenging and is certainly demanding to keep up to speed with everything. In my function, I am often involved in multifunctional communications, but within this project the speed and amount of information going through is impressive to witness. This makes the emphasis on proper information sharing and managing all that more important. What is striking me in this project is the effort people are putting into their work and the willingness of everyone to go the extra mile to make this a success."

Together with a global pharmaceutical company for quality control activities of COVID-19 vaccines

Two pharmaceutical companies have been partnering to develop new generation vaccines. As a strong partner to support vaccines companies, Avertim has been asked to provide its support in preparing clinical and commercial production. A team of consultants ae currently working on:

- Scaling-up of commercial production

- Supporting QA and QC

- Validating QC equipment for RNA testing

- Validating production processes

Together with a French pharmaceutical site for the production of a vaccine component

A global vaccine manufacturer is in charge of manufacturing a component of a COVID-19 vaccine candidate. Avertim has been working on the project since June 2020 to prepare the site for production especially bulk filling activities.

- Coordinating local bulk activities and transfers

- Upgrading equipment

- Validating processes and submiting changes to authorities

- Transfering QC methods

Our Principal Consultant involved in the project shares his feedback

" Our customer is highly involved in the covid-19 value chain as he is producing a key component which will increase the efficiency of the vaccine. My role is to support the site leadership team organizing the production start-up and ramp-up. Together with the team, we make sure that the right activities are prioritized, and all risks are mitigated properly. A pluri-disciplinary team has been formed, including technical experts, production managers, qualification and quality experts. This collective effort involves several sites of the company and external players (Contract Manufacturers and other pharmaceutical firms). My next challenge is to build 2021 operational budget which will allow the organization to hire enough talents to deliver production to plan."